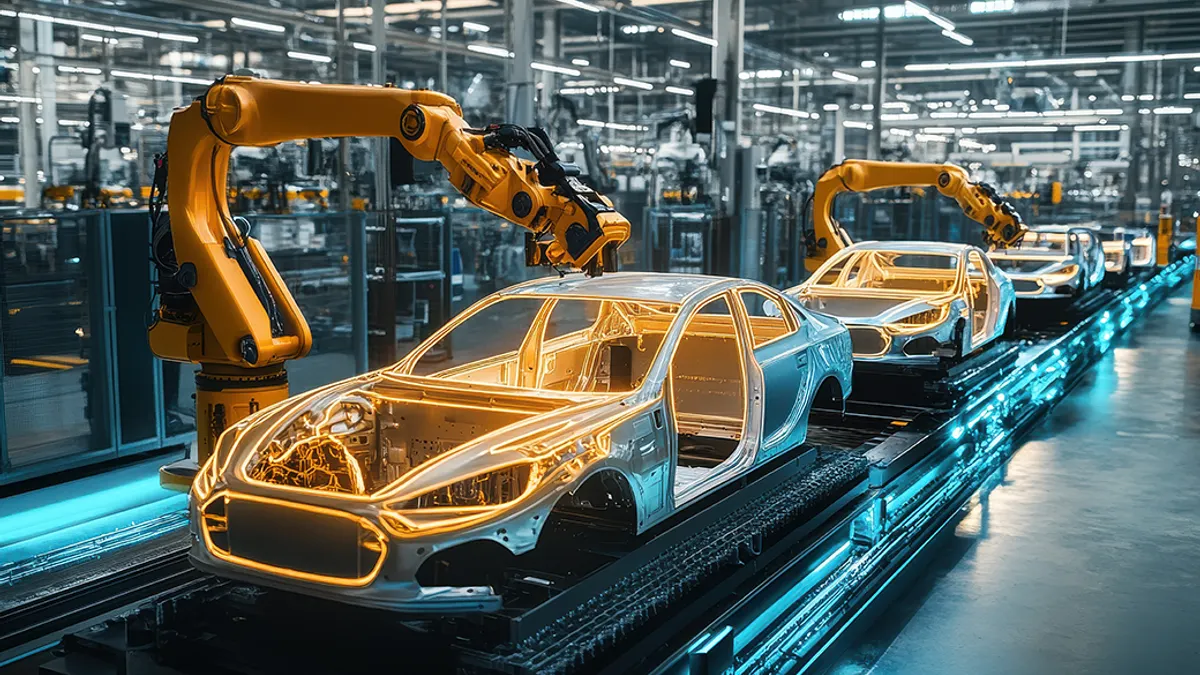

From automotive to aerospace, the modern US manufacturing industry has become a global operation by default. Whether sourcing raw materials or assembling products, manufacturers today rely on a web of factories, suppliers and partners scattered across the world. A single car may contain parts made in a dozen different countries – all brought together through complex, digitally connected supply chains.

In the case of US automotive technology manufacturer Visteon, “network connectivity is professional oxygen for us,” says the company’s Global CIO, Raj Singh. That cross-border network enables manufacturing companies to grow and scale around the world.

But at the same time, connecting operations across continents, time zones, multiple suppliers, and regulatory regimes introduces new levels of complexity and risk. Internet connectivity varies dramatically by region, too. Local telecom standards are inconsistent, and compliance requirements differ – sometimes subtly, sometimes starkly – across borders.

For US manufacturers looking to expand or diversify globally, each of these differences becomes a point of friction. One wrong configuration can cause downtime across a region, just as choosing the wrong partner can compromise compliance – even putting the business at legal risk.

That’s why CIOs now sit at a critical junction between the forces shaping global supply chains. And as the world becomes more complex, the unprepared or unsupported CIO risks seeing their business become tangled up in the very infrastructure that was meant to support it.

But those who work with the right partners – and make intentional moves early – can turn complexity into a competitive advantage, driving long-term agility, resilience, and growth.

Digital infrastructure is a supply chain decision

US firms are increasingly embracing supply chain diversification through nearshoring and multi-regional strategies - to increase flexibility and reduce overreliance on any single geography. This may include for example supplementing their operations in markets like China with facilities in places like Vietnam, India and Malaysia.

When they do this, however, they’re also making digital infrastructure decisions. Whether you’re onboarding a new supplier or opening a new plant, seamless connectivity and data control are non-negotiable.

Each new country adds another layer of complexity and risk: different ISPs, variable infrastructure maturity, unfamiliar security and privacy laws. Even “less regulated” markets can pose risks for US-based teams.

Here, CIOs can play a uniquely strategic role by recognizing that the infrastructure they choose to build isn’t just a technical concern – it underpins compliance, efficiency and business continuity. So, the right decisions can enable smooth overseas expansion, while the wrong ones can introduce costly surprises.

But it’s unrealistic for any CIO to expect to be able to master or navigate every country’s telecom landscape or regulatory environment. That’s why the most successful global manufacturers work with partners who offer:

- Regional expertise – from licensing and data governance to last-mile connectivity

- On-the-ground presence – hands-on support when onboarding suppliers or resolving local issues

- Technical fluency – ensuring global standards are met, even in unfamiliar territories

“Companies want a partner who understands the key markets they operate in, and the regulations in each place,” confirms Jay Pandarinathan, Regional Head of Enterprise Business at Tata Communications. “We can take care of that complexity, allowing them to focus on other priorities.”

For instance, Tata Communications was brought in to help simplify the network ecosystem of a large industrial manufacturer, which operated in over 180 countries and had more than 40 different network providers supporting its global footprint.

By consolidating providers, streamlining connectivity, and standardizing infrastructure across regions, Tata Communications injected visibility, scalability and control into a previously fragmented global network.

As Raj Purkayastha, VP Head of Pre Sales and Strategy, Americas at Tata Communications, put it: “When CIOs face dozens of telecom standards, multiple suppliers and fragmented regulation across markets, they don’t just need another product – they need a guide. Our role is to uncomplicate the landscape, connect the dots, and enable our customers to move forward with confidence.”

A partner for Asia-Pacific, Middle East and India

Much of today’s manufacturing diversification is happening in emerging regions, such as APAC, the Middle East and India, driven by both cost and capability. Hugely diverse and complex regions from a supplier and regulatory perspective.

As George Michalitsianos, Vice President of Information Security at global manufacturer Ansell, observes: “One of the benefits of working with Tata Communications is its global presence and its ability to provide IT services and global managed services across a plethora of countries. That’s where Tata Communications can exceed a lot of other partners, due to its international capabilities, especially within Southeast Asia.”

When done correctly and delivered on time and on budget, supply chain diversification can offer another layer of strategic resilience to infrastructure planning. For instance, when working with a global manufacturer expanding into Vietnam, Tata Communications helped it design a network model that complied with local data laws while still integrating seamlessly with the company’s global systems.

Approaching diversification like this can be a powerful strategy in uncertain times. But if not managed carefully, it may create more hindrances than benefits.

CIOs – the champions of global resilience

As the world grows more unpredictable and innovation accelerates, expect the manufacturing landscape to continue to fragment. But while supply chains may evolve, international operations will undoubtedly remain essential.

For CIOs, this is about more than managing networks or vendor contracts. It’s about enabling strategic flexibility and operational resilience. That’s a tall order – but with the right support, it’s achievable.

So, if you’re planning your next move – a plant in Mexico, a supplier in Vietnam, or a logistics partner in Dubai – ask yourself: will your digital infrastructure enable the opportunity, or stand in its way?

With the right partner, it doesn’t have to be a gamble.